Workforce Agility Approach

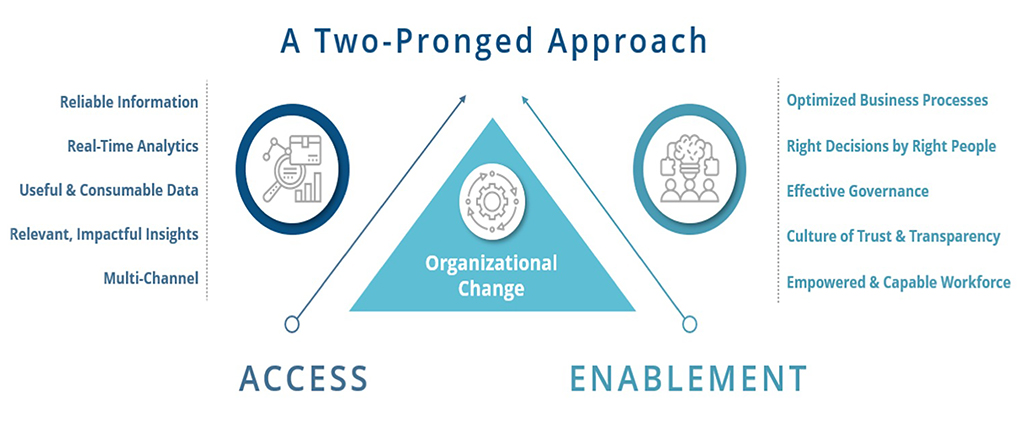

Through times of incredible change and uncertainty, there are winners and losers. Those who can adjust to change and even thrive during uncertainty, end up taking market share and driving profitability – capitalizing on destabilizing events. Winning requires agility. Workforce agility comes from an appropriate balance of access to information and decision-making authority for employees, which results in higher performance. The information must be reliable, timely, useful, relevant, and from a range of sources. However, employees must be enabled to do something with the information. Decision rights must be granted to them at the right levels of the organization for the right business processes while fostering a culture of trust and transparency.

Creating an agile workforce does not happen overnight, it is an ongoing process and requires continuous improvement. Recognizing where your organization currently is and where it strives to be is the first step towards progress. Giving employees the information they need and the decision rights they deserve will unlock the performance of your people and organization.

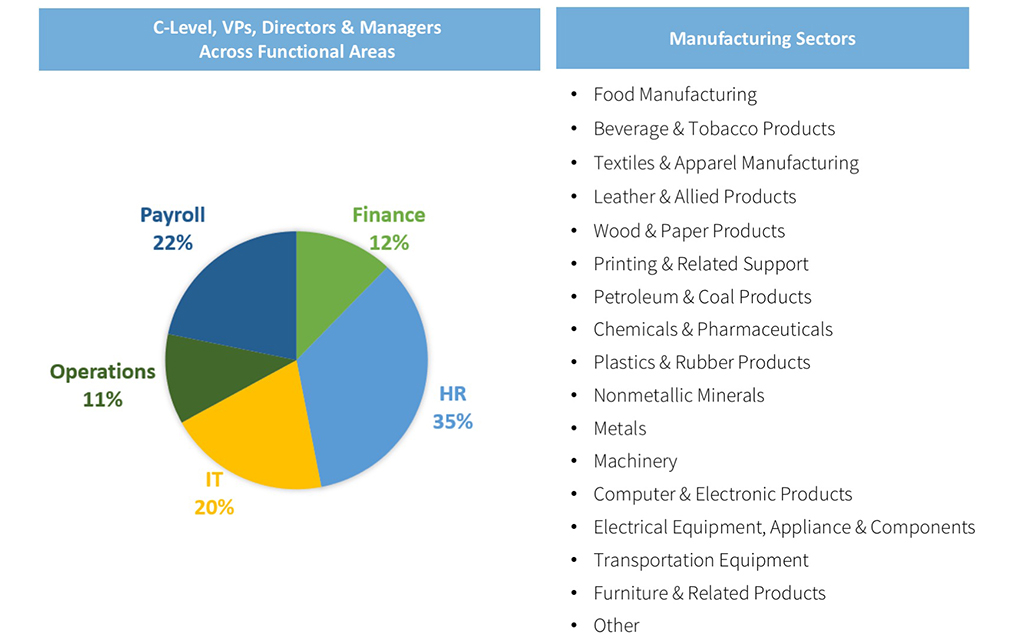

With the help of the Workforce Agility Survey, new insights into areas of opportunity were uncovered. Ankura and Workforce Insight collaborated to create a 30-question survey based on the principles of access and enablement. Possible responses were based on a Likert scale of 1-5, with 5 being the most positive. The combination of all responses was combined to create a maturity score. The higher the score, the more agile the organization. The manufacturing sector had strong participation, including several sub-verticals, as well as a range of functional areas illustrated below:

Agility by Industry

The manufacturing sector has not been a leader in the field of agility and that was clear in the results of the study. In fact, based on the Workforce Agility Survey, manufacturing scored last in agility out of all industries that participated. This result is not because manufacturing is stagnant, instead, it highlights that people performance has not been a high priority. Technology and automation for production and supply chain have consumed budget allocations leaving less to develop human capital. Other sectors have fared much better, especially those that are customer-facing such as healthcare and retail. Employee performance is a necessity to deliver good outcomes in healthcare, and in retail, employee performance is directly correlated with revenue.

Agility Score by Industry

Additionally, warehousing and other supply chain strategies have historically created buffers that shield manufacturing facilities from having to flex up and down to consumer demand. The need for agility was less critical when consumer demand did not have a direct impact on manufacturing, and the demand curve could be handled within the current infrastructure. That infrastructure broke during the pandemic.

The Case for Agility in Manufacturing: The Test That Broke the Supply Chain

The COVID-19 pandemic tested strategies for warehouse consolidation, and in many cases the supply chain was not capable of delivering products to satisfy panic buying. As consumers created a new network of personal warehouse space – their basements or storage closets – a massive disruption for manufacturers ensued. We learned very quickly why agility is so important.

Over the last several decades forecasting demand has become more precise, although manufacturers will argue it still has a long way to go. This continuous improvement gave large, global brands the ability to consolidate warehousing space and carry less inventory.

“The effort to become ‘just in time’ producers of consumer goods drove down inventory costs and squeezed out additional profit. This ‘leaning out’ of the supply chain was celebrated as progress.”

The lean supply chain was never engineered for the type of panic buying seen at large scale in 2020, spurred on by the pandemic. Shelves quickly emptied of essential items causing manufacturers to ramp-up production without the infrastructure to support it.

This was unforeseen consumer behavior. Customers were not consuming the products they were buying but storing them in their homes, therefore creating a new type of “consumer” warehousing in the supply chain. As concerns over supply eased, consumers began using the products from their own warehouse storage, decreasing demand at the store level. This caused a backup in “real” warehouses as manufacturing sites were now overproducing. The initial shockwave that caused the ramp-up in production was now having the opposite effect, a sharp decline in demand causing a dramatic ramp down in production.

The Case for Agility in Manufacturing: The Test That Broke the Supply Chain

Sectors with the biggest gaps in supply chain agility also saw switching behavior among consumers. When the shelves were empty of one’s preferred brand, consumers purchased whatever was available and those who were on the shelf gained new customers for life. This customer acquisition trend deriving from product availability (or lack of availability) will have an impact on demand long after the pandemic is over.

So, what does this mean for people performance? As shockwaves continue to reverberate through the supply chain, employees are being asked to be more agile than ever. The amount of overtime worked during the pandemic for many of these employees is unsustainable, and fear of reduced hours below the traditional 40 is now a real fear as consumer demand flexes dramatically. This type of whiplash is especially painful for companies who have not created agile labor strategies and systems to handle such fluctuations.

As exhausted as we all are right now, there is no better time to assess what has happened, develop the right labor strategies and prepare organizations to be resilient to the next big disruption. It is not a question of if, but when it will happen again. Ankura and Workforce Insight embarked on a study to understand where weaknesses exist in manufacturing and in other industries that limit agility, and the implications it has on people performance.

Workforce Agility: The Manufacturing Results

Agility by Function

We looked at the results of the study by function in the manufacturing sector to uncover the

different perceptions of agility based on where someone sat in the organization. It was no surprise that Finance felt the most enabled considering the role they play and the need to act on key financial responsibilities. It was disheartening to see that IT and Operations felt they had more access to information than Finance, considering the responsibilities of Finance and the importance of information access to be successful.

It was particularly interesting that the Executive Office was the least positive about both aspects of agility within their organizations. Perhaps the birds-eye view that an executive has reveals the gaps, which is why we see them pushing aggressively for transformation. They see the opportunity and know how much upside is available.

A Culture That Speaks to Empowerment vs. One That Enables Empowerment

One very clear finding that came out of the study was that manufacturing employees feel like they have a culture of empowerment. However, they are less positive about their ability to get the information they need to perform. When reviewing the most positive responses (a 4 or 5) to the questions in each category, the differences became even more clear. A Culture of Enablement was the highest scoring with 217 high ratings, compared to the lowest scoring Access – Consumable with only 47 high ratings. What does this mean? Talking to employees about empowerment and making them feel enabled is much easier than actually equipping them with the tools and information they need to make changes effectively. Without intentional efforts to provide employees with access to information, manufacturing companies will continue to lack workforce agility.

The Top Performing Categories for Agility

For further detail on this finding, we have listed the questions from the two highest and two lowest ranked categories:

For Enablement – Culture, we asked the following questions with the potential responses from 1-5, 5 being the most positive:

- Has a culture that supports an environment where it is safe to debate or offer different points

of view - Provides a leadership team that is actively involved in change initiatives

- Ensures that employees feel empowered throughout the organization

- Clearly communicates goals/objectives

- Has had success with most past change initiatives

For Enablement – Governance, we asked the following questions with the potential responses from 1-5, 5 being the most positive:

- Ensures that projects are always aligned to the strategic initiatives of the organization

- Effectively prioritizes projects and focuses resources on the most important projects

- Establishes clear ownership for all labor/workforce related programs and projects

- Is effective in decision making related to labor/workforce related projects

- Ensures that labor/workforce related initiatives deliver the intended results

The Bottom Performing Categories for Agility

For Access – Actionable, we asked the following questions with the potential responses from 1-5, 5 being the most positive:

- Provides self-service tools that make interpretation of workforce data easy for front-line managers to act upon

- Automates data sharing and notifications to enable action on critical leave and attendance events

- Provides decision makers with timely access/views to identify and address potential

compliance issues - Provides decision makers with timely access/views to identify and address potential gaps in staffing levels and coverage

- Delivers visualizations that enable efficient adaptation of staffing and scheduling strategies

For Access – Consumable, we asked the following questions with the potential responses from 1-5, 5 being the most positive:

- Considers all data stakeholders across the organization in defining and delivering labor related data visualizations (charts, graphs)

- Provides managers and employees with data visualizations that make relevant insights easier to understand

- Uses narratives and storytelling to help convey the meaning behind data to everyone involved in the process of decision making

- Delivers visualizations that enable efficient adaptation of staffing and scheduling strategies

- Consistently monitors how data is used across the organization to make interpretation of data more consumable and meaningful

The Impact of Modern Digital Platforms

The newest platforms that enable workforce performance are driven by cloud architecture, artificial intelligence, and leverage mobile to push information to employees through multiple channels. These modern digital platforms have not been around for more than a few years, but have already been making a significant impact on workforce culture. Employees can check vacation balances, swap shifts, make themselves available for overtime, and communicate with managers in real-time. This gives them more freedom and flexibility while helping their organizations to become more effective and agile with labor management. Management teams can leverage these new platforms to access the data they need to understand performance, make staffing adjustments before the shift is over, and move employees to fill open slots based on skill, proficiency, and availability. This dynamic digital ecosystem drives results for the business, and provides more value to the workforce than legacy systems ever did. Everyone wins.

The table below shows how modern technology enables workforce agility by improving the way

teams can access information and make decisions that drive change.

Final Remarks

43% of respondents believe their organization lacks enterprise-wide visibility to the right data to effectively adjust staffing models in response to changing business demands.

In conclusion, workforce agility can transform performance by leveraging the most powerful resource in an organization – the people. Breaking down this approach into two simple pieces will allow all levels of the organization to assess where they sit on the maturity curve. Do your employees have access to the information they need in a useful format so they can make better decisions faster? If they do, have you allowed them to have the decision rights to actually make the changes? The balance between access and enablement is the key to agility. Finding that balance means unlocking the power of your people.

© Copyright 2021. The views expressed herein are those of the author(s) and not necessarily the views of Ankura Consulting Group, LLC., its management, its subsidiaries, its affiliates, or its other professionals. Ankura is not a law firm and cannot provide legal advice.